High-level technical overview

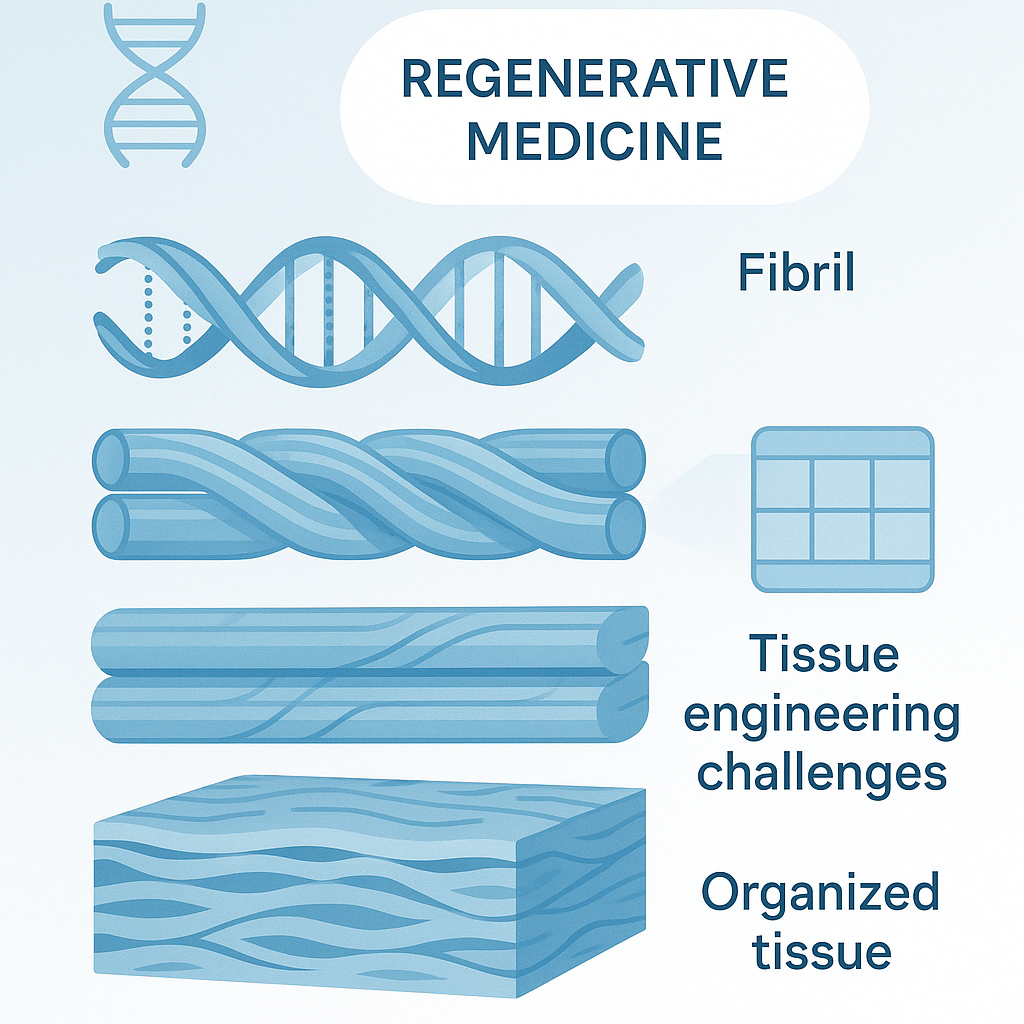

Collagen’s triple-helical α-chain trimer self-assembles into quarter-staggered fibrils that further bundle into load-bearing fibers, creating a multiscale architecture unrivaled among extracellular matrix (ECM) proteins. This hierarchy provides essential features such as tensile strength, cryptic integrin-binding motifs (GFOGER, DGEA), and nucleation sites for mineral ions, which are critical for modern regenerative medicine platforms to exploit Source: Frontiers in Bioengineering and Biotechnology.

Hierarchical design principles

Collagen’s architecture spans at least four nested length scales, each contributing distinct mechanical and biochemical signals necessary for effective tissue engineering. The structural fidelity at these scales is crucial:

- Nanoscale fidelity: Electro-compaction or magnetic alignment of type I collagen preserves native D-band periodicity, yielding ribbons with high tensile modulus (>150 MPa), guiding mesenchymal stromal cells toward tenogenic differentiation Source: Frontiers in Bioengineering & Biotechnology.

- Microscale guidance: Directional freeze-casting leads to lamellar pores that effectively steer progenitor cells and nascent capillaries, enhancing osteochondral integration Source: Journal of Leather Science & Engineering.

- Mesoscale reinforcement: The twisting of aligned fibers into fascicle-like bundles allows for increased ultimate stress, enhancing the mechanical properties while maintaining critical inter-bundle nutrient diffusion channels Source: Frontiers in Bioengineering & Biotechnology.

- Macroscale anisotropy: 3D printing gradient-density collagen inks facilitates the transition from compliant cartilage-like zones to stiff bone-like regions, allowing for restored joint biomechanics in large animals Source: Journal of Leather Science & Engineering.

The effectiveness of scaffold design in tissue engineering is correlated to how well it replicates collagen’s multiscale hierarchy, influencing mechanotransduction and functional tissue regeneration.

Tissue-specific applications

Tailoring collagen applications to specific tissues showcases the protein’s versatility in regenerative medicine. Examples include:

- Bone & dentine: The co-assembly of collagen with hydroxyapatite nanocrystals creates a biomimetic composite, promoting accelerated cranial defect closure in rat models Source: Nature Communications. Proanthocyanidin-mediated intermolecular bridging enhances the modulus of dentin collagen and promotes remineralization Source: Materials & Design.

- Cartilage: Injectable type-II collagen hydrogels blended with self-assembling peptides restore hyaline cartilage under large-scale defect conditions Source: Journal of Leather Science & Engineering.

- Skin: Drug-eluting collagen membranes combined with platelet-rich plasma expedite healing in full-thickness porcine wounds Source: Journal of Leather Science & Engineering.

- Cornea: Cross-linked recombinant human collagen type III implants maintain corneal transparency and promote nerve density restoration without graft rejection during a four-year follow-up Source: Frontiers in Bioengineering and Biotechnology.

Bone and dentine regeneration

Collagen’s role in bone and dentine regeneration is multifaceted. The molecular interactions at play include:

- Hierarchical collagen/apatite co-assembly: This method rapidly polarizes macrophages toward an M2 phenotype, promoting efficient bone defect closure Source: Nature Communications.

- Bioactive cross-linking: Polyphosphate cross-links not only promote hemostasis but also enhance bone fill in canine tooth-extraction models Source: Bioactive Materials.

- Topological control: The integrity of collagen fibrils is vital as it influences osteoblast proliferation and MSC differentiation towards osteogenic lineages Source: Frontiers in Bioengineering & Biotechnology.

Bioactive functionalization strategies

Strategies for bioactive functionalization of collagen scaffolds include:

- Growth-factor immobilization: Peptide amphiphiles enhance BMP-2 delivery, achieving bone union at lower cytokine doses Source: Biomaterials.

- Immuno-modulating grafts: The addition of RGD peptides has been shown to significantly enhance macrophage polarization, promoting an M2 phenotype without compromising structural integrity Source: Frontiers in Bioengineering & Biotechnology.

- Mechanical stabilization: Various techniques such as genipin cross-linking and microbial transglutaminase can enhance collagen’s structural properties while maintaining bioactivity Source: Bioactive Materials.

These functionalization strategies enable the evolution of collagen scaffolds from passive supports to active interfaces capable of controlling healing environments.

Challenges & future directions

Despite advances, the field faces significant challenges, including:

- Batch variability: Variances among animal-derived collagen sources lead to unpredictable mechanical properties and biological responses Source: The Influence of Animal Species on Collagen Sponges (Springer).

- Regulatory hurdles: The classification of collagen products by regulatory agencies may complicate market access, particularly when combined with biologics Source: Frontiers in Bioengineering & Biotechnology.

- Cross-linking technology limitations: Traditional methods like glutaraldehyde present cytotoxicity issues, while newer techniques need to achieve scalability in production without losing the benefits of biocompatibility Source: Bioactive Materials.

- Emerging manufacturing innovations: New methodologies such as 4D printing and continuous reactive systems may shift the paradigm of collagen scaffold fabrication, improving consistency and lowering costs.

Meeting these challenges will require collaboration across the industry to standardize benchmarks, enhance production strategies, and ensure regulatory compliance.

Sources

- Bioactive Materials – Polyphosphate-cross-linked type I collagen sponges couple rapid ionic clot formation

- Biomaterials – Heparin-mimetic peptide amphiphiles self-assemble within collagen pores

- Frontiers in Bioengineering and Biotechnology – Collagen and Its Applications in Tissue Engineering

- Journal of Leather Science & Engineering – Review on Collagen-based Biomaterials for Tissue Engineering Applications

- Nature Communications – Hierarchical collagen/apatite co-assembly

- Materials & Design – Proanthocyanidin-mediated intermolecular bridging in dentine regeneration

- The Influence of Animal Species on Collagen Sponges (Springer)